Dryers

About Equipments

DTA Engineering provides high-quality dryer equipment, including heating elements, air circulation systems, control panels, and moisture sensors. Our advanced technology ensures efficient drying processes for various industries, enhancing performance, energy efficiency, and durability. Trust DTA Engineering for reliable dryer solutions tailored to your needs.

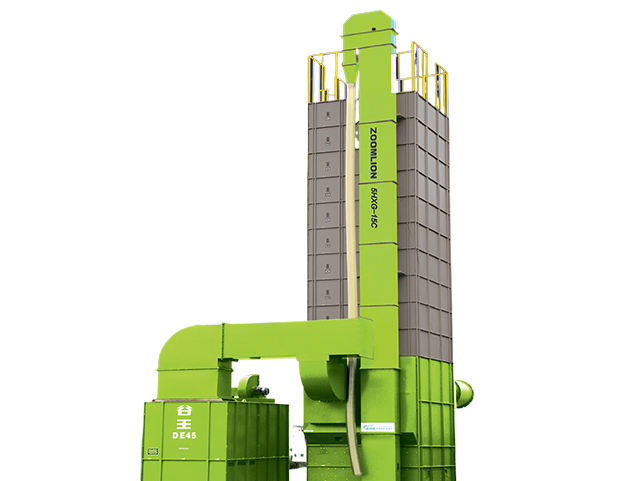

Grain Dryers

Technical Specifications

Grain dryers

| Dryer type | Batch Type Circulating Dryer |

| Power supply | Three-phase:220V/60HZ, 380V/50HZ |

| Total power | 16.57kW |

| Capacity -Rice | 7500-30000kg |

| Capacity -Wheat | 9100-36500kg |

| Hot air temperature | 30-120°C |

| Drying ability | Rice≥6, Wheat≥7t*%/h |

| Hourly drying rate | 0.6-1.2%/h |

Electric Heaters

Technical Specifications

Electric Heaters

model | Unit | PZZH360S-50P | PZZH360S-60P | PZZH360S-100P | |

capacity | kW | 200 | 240 | 400 | |

working humidity | °C | 75 | 75 | 75 | |

consumption of electrical nergy approx. | kW/h | 35.7 | 60 | 104.8 | |

dimensions( L*W*H) | / | 2550*1315*2440 | 2550*1225*2673 | 2813*2550*2500 | |

machine Weight | / | 1050 | 1150 | 1255 | |

dryer quantity(max) | 5HXG-10W | 1 | – | – | |

5HXG-12.5W | 1 | – | – | ||

5HXG-15W | – | 1 | – | ||

5HXG-30W | – | – | 1 | ||

Biomass Pellet Furnaces

Technical Specifications

Biomass Pellet Furnaces

model | unit | 5LLS-12KA | 5LLS-50KA | 5LLS-60KA | 5LLS-75KA | 5LLS-100KA | 5LLS- 130KA |

thermal power approx. | kcal/h | 120000 | 500000 | 600000 | 750000 | 1000000 | 1200000 |

Bio-particles consumption amount approx./ Bio-particles energy =3600 approx. | kg/h; Kcal/kg | 36 | 150 | 181 | 226 | 301 | 362 |

power | kW/HP | 4.05/5.4 | 4.05/5.4 | 4.85/6.46 | 4.85/6.46 | 6.2/8.2 | 10.2/13.6 |

dimensions(L*W*H) | mm | 2180*1200*1600 | 4460*1600*2250 | 4460*1600*2550 | 5040*1600*2250 | 5200*1900*2850 | 5300*2000*2850 |

machine weight | kg | 4000 | 4500 | 5000 | 5500 | 8000 | 9000 |

safety devices | / | Thermal relay, abnormal overheat detection, flame failure detection, fully automatic abnormal fault interlocking device, control fuse. | |||||

dryer quantity(max) | 5HXG-10W | 1 | 3 | 5 | 7 | 8 | 10 |

5HXG-12.5W | 1 | 2 | 4 | 6 | 6 | 8 | |

5HXG-15W | – | 2 | 3 | 5 | 6 | 7 | |

5HXG-30W | – | – | – | 2 | 3 | 4 | |

Rice Husk Suspension Furnaces

Technical Specifications

Rice Husk Suspension Furnaces

model | unit | HB-80KA | HB-120KA | HB-150KA | HB-180KA | HB-220KA | HB -260KA | HB-300KA | HB-360KA |

max thermal power approx. | kcal/h | 800000 | 1200000 | 1500000 | 1800000 | 2200000 | 2600000 | 3000000 | 3600000 |

husk consumption amount approx./ husk energy = approx. 3100 Kcal/kg | kg/h; | 235 | 375 | 470 | 580 | 680 | 780 | 880 | 1020 |

ash discharge approx. | kg/h | 30 | 49 | 61 | 75 | 85 | 95 | 110 | 135 |

power | kW/HP | 13.75/18.3 | 13.75/18. | 3 15.7/20.9 | 19.25/25.6 | 23.25/31 | 23.25/31 | 30.25/40.3 | 30. 25/40.3 |

dimensions( L*W*H) | mm | 6830*2940*9145 | 6830*2940*10365 | 6830*2940*10365 | 6150*3840*11080 | 6700*4000*11080 | 6900*4000*11080 | 11000*3900*7200 | 7300*4200*1080 |

machine weight | kg | 13500 | 15500 | 17800 | 19500 | 21200 | 23800 | 28000 | 31500 |

safety devices |

| Thermal relay, abnormal overheat detection, flame failure detection, fully automatic abnormal fault interlocking device, control fuse. | |||||||

dryer quantity(max) | 5HXG-10W | 7 | 10 | 13 | 15 | 18 | 21 | 24 | 29 |

5HXG-12.5W | 6 | 9 | 12 | 14 | 17 | 20 | 23 | 28 | |

5HXG-15W | 5 | 8 | 10 | 12 | 15 | 17 | 20 | 24 | |

5HXG-30W | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

Cleaning Sieves

Technical Specifications

Cleaning Sieves

model | unit | TSCY150 | TSCY180 | YTQZ180*2 |

capacity | t/h | 20-25 | 25-45 | 30-50 |

power | kW/HP | 2.2/3 | 3/4 | 10/13.5 |

dimensions( L*W*H) | mm | 2750*1340*1760 | 3240*1650*2030 | 4400*2200*3500 |

machine weight | kg | 610 | 1200 | 1400 |

project | ton | <100 | <200 | <300 |

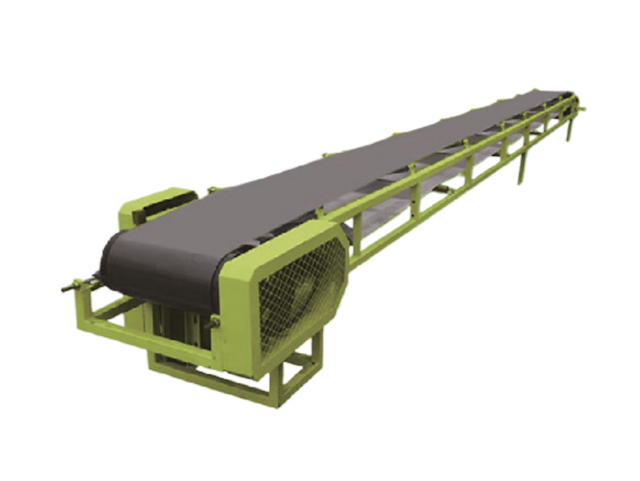

Conveyers

Technical Specifications

Conveyers

model | unit | TGSG600 | TGSG800 | TGSG100 |

output | t/h | ≥60 | ≥80 | ≥80 |

power | kW/HP | 4/5.5 | 7.5/10 | 30/40 |

project | ton | <100 | <200 | <300 |

Other Products

- Elevators

- Silos

- Fuel oil and gas burners